Company

Factory Show

Since founded in 2005, we focus on the storage racking till now, at the beginning, from the basic standard heavy-duty pallet racking and medium duty shelving, then, developed a series of other types of racking, such as: drive in racking, semi-automatic shuttle racking, America standard teardrop pallet racking, push back racking, mezzanine rack, mezzanine floor, and other customized products. After these years’ spreading, almost covers all the racking type used in the market.

01

Our factory area is from thousands of square meters develop to around 50000 square meters, workshop fixed with advanced technology equipment, upright rolling line, beam rolling line, punch hole machine, bending machine, powder coating lines.

With the developing of new racking type, we build many new production lines with new dies, such as the one for teardrop racking, as the business in USA market grows greatly, we made 3 more punching and rolling lines for the teardrop pallet racking.

02

03

As the delayed shipment happening frequently in China, in order to improve our production rate, we have purchased several automatic welding robots, which is not just improving speed, welding in a more beautiful uniform surface, also saved labor cost (as the labor cost is increasing greatly these years in China.

Moreover, we purchase several automatic welding machines for beam connector welding.

Some of them can weld two beams at the same time, improving the welding speed greatly.

Automatic Powder Coating Line, long enough to speed turn over time of the whole line, painting automatically, make sure the smooth of the surface appearance, keep the quality and speed, and friend to environment.

04

05

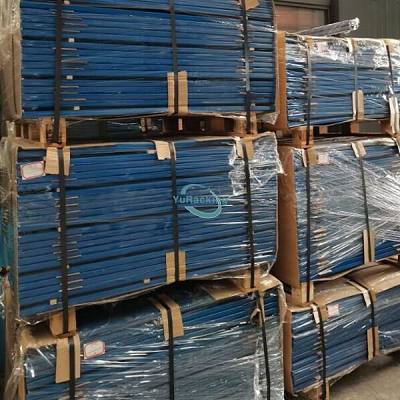

Warehouse-Packing in Pallets, in order to strengthen the whole pallets, avoiding any damage in the container in shipping process, we use the very strong wooden pallet, the raw wood with Fumigation Certification, also strong plywood pallet. And also use the thick carton plate, small carton board, steel band to fix the pallet tightly.