Here YuRacking will show a case of FMCG warehouse rack storage solution we made before to make you better understand how FMCG warehouse works. The whole FMCG warehouse system is totally 5332pcs pallet positions: Shuttle Racking System(1680pcs) + VNA pallet racking (3652pcs).

Brief Introduction of FMCG Warehouse Rack Case Background

This customer makes business of electronic products. When he sent their warehouse layout to us at the first time, which shows the sizes (length, width, height) of his warehouse in details, we found that this warehouse is very high. So, we communicated with him to get a deeper understanding of his warehouse, and got his demands in details. He has many stores in the local market and other regions, thus has a big quantity of goods in stock. Some types (especially the hot sale ones) of goods are especially in large amounts. Also, there is a need for storing lots of other different kinds of products. He told us that he needs the FMCG warehouse to be in organized way, and because the whole FMCG storage system is often at a stage of high-speed flow, so it is necessary to maximize the space use of the FMCG warehouse.

How YuRacking Help Customers to Solve FMCG Storage Problems

After getting above information, our engineer analyzed this warehouse rack layout carefully. Considering the warehouse is high, we confirmed the high-density solutions firstly:

As Some Hot-sale Products is in Big Qty, We Advised Using Pallet Shuttle Racking System in Parts of the FMCG Warehouse

The reasons are as follows:

· The Pallet Shuttle System is suitable for big qty SKU;

· It is a semi-automatic system featuring high efficiency storage, and the shuttle car can be in a speed to 30-50m/min with full loading;

· The Shuttle Racking System can save both space and labor;

· FMCG racks can be customized in 5-8 levels to maximize the usage of high space.

For Other Types of Products, We Advised to Use Very Narrow Aisle Racking (also Called VNA Pallet Racking) at the Left Side of the FMCG Warehouse:

The reasons are as follows:

· VNA Pallet Racking is good to store different kinds of products, and goods can be picked up in both sides;

· Forklift can load and unload any cargos very easily;

· The VNA Pallet racking can maximize the space use, both in floor size and high space.

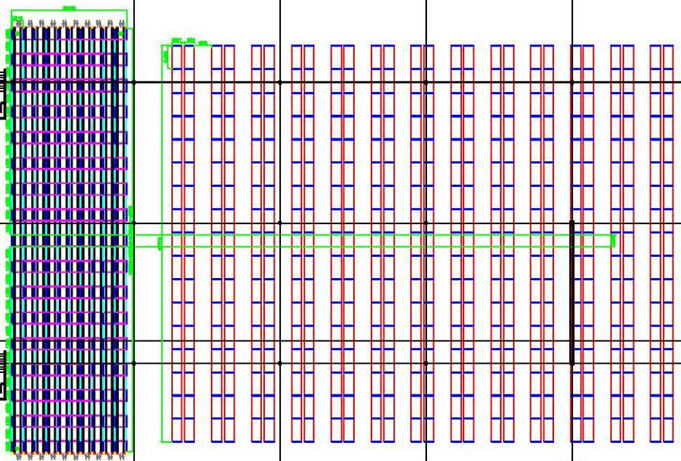

Here We Shows the layout of Finished FMCG Warehouse Rack System:

The final FMCG warehouse distribution layout is as the above design, we also choose the suitable shuttle cars for the Shuttle Racking System; Meanwhile, we advised him to buy special forklifts for the Very Narrow Aisle Pallet Racking. Everything goes smoothly, we finished shipping and installation of FMCG warehouse rack storage. Till now, the whole warehouse racking system did a very good job, realizing all the functions he emphasized. Here comes his feedback:

the racking system improved our management greatly, and I will recommend your job to my friends.

The Following are the On-site Pictures the Customer Sent to us:

In conclusion, as we see, to make a perfect industrial shelving storage solution, except the professional engineers, the customer's cooperation is also needed. A great communication between the supplier and the customer can make the custom FMCG warehouse demands clear step by step.

If You need FMCG Warehouse Storage Solutions as Well, Welcome to Contact us and Provide the Following Information:

Before solution confirmation, better for us to know the below details information:

· What're the cargos need to keep: in heavy duty forklift loading-pallet racking or light-medium duty hands loading-warehouse shelving;

· Warehouse Layout in details size (length, width, height), door/post position;

· Rack size: L/W/H, or pallet size (length, width, height=pallet height + goods height); or carton/box size;

· Load capacity: kg/level or ?kg/pallet or ?kg/carton;

· How many levels need?

· Warehouse storage demands, space usage?

· material handling processes & picking speeds

With these data, our engineers can design a suitable and reasonable storage racking solution for your warehouse. That's the most economical way to find out the better solution together. If your need a complex FMCG warehouse storage solution with complex cargos storage needs, such as the automatic system, and you have enough budget, we also can arrange our engineers to your warehouse to confirm in the site. Get a Quote Now!

Related Racking and Shelving Services

Related Racking and Shelving Products

Selective Pallet RackingSelective Pallet Racking is the most economical pallet racking solution, 100% selective

Selective Pallet RackingSelective Pallet Racking is the most economical pallet racking solution, 100% selective Narrow Aisle Pallet RackingNarrow Aisle Pallet Racking-high density solution, the aisle is just need 1.6m-1.8m

Narrow Aisle Pallet RackingNarrow Aisle Pallet Racking-high density solution, the aisle is just need 1.6m-1.8m Double Deep Pallet RackingDouble Deep Pallet Racking-four bays together, high density, need the special double deep forklift

Double Deep Pallet RackingDouble Deep Pallet Racking-four bays together, high density, need the special double deep forklift