Drive in Pallet Racking is a high-density warehouse racking solution, 6-7 pallets position per depth row, one row next to the other, for a certain area. The drive in and drive through pallet racking system needs no aisle among the rows, and the forklift goes into the depth to load/unload pallets one by one, usually, it is FILO (first in last out).

Compared with the other conventional pallet racking system, such as double deep racking or narrow aisle racking, drive in racking system, much less aisle need, maximize the space usage, for a better handling, 7 pallets position in one depth row at most is suggested, height levels can be 4-8 pallets position, depends on warehouse storage demands, the pallets also can put on the floor level directly. Usually, the working area is in one side. Also, can be designed FIFO (first in first out), that's the drive through pallet racking, drive through racking, can pick up the pallets from two sides, so, realize first in first out. Whether drive in pallet racking or drive through pallet racking, YuRacking has both of them for sale.

The Features of Drive in Pallet Racking

The most high-density solution, 85-90% space usage;

FILO mode mostly;

Fewest aisle, one row next to the other rows;

Ideal to keep the same big qty SKUs;

Floor space saving, cost effective solution.

The Specification of Drive in Pallet Racking

Drive in Pallet Racking Upright Frame Load Capacity

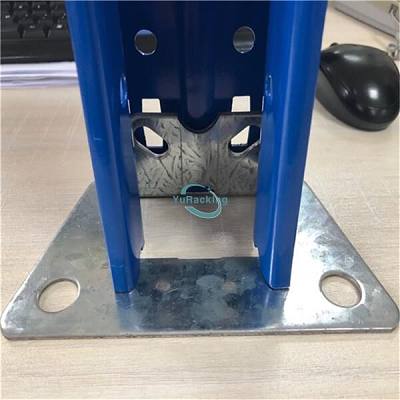

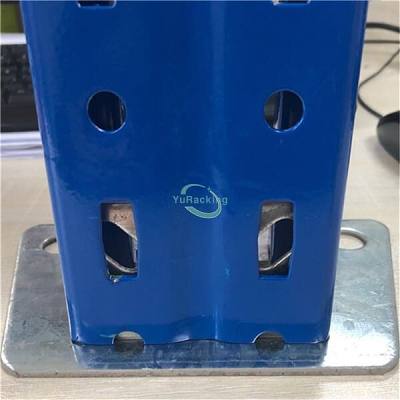

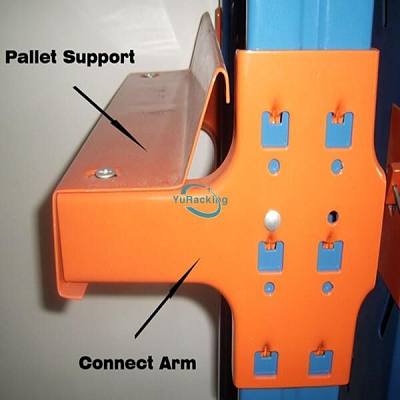

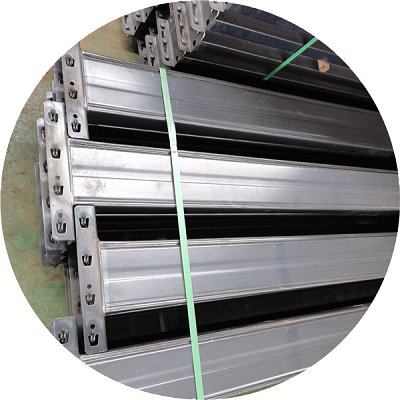

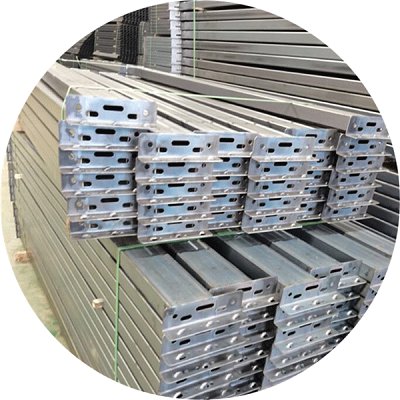

Drive in Pallet Racking Parts & Accessories

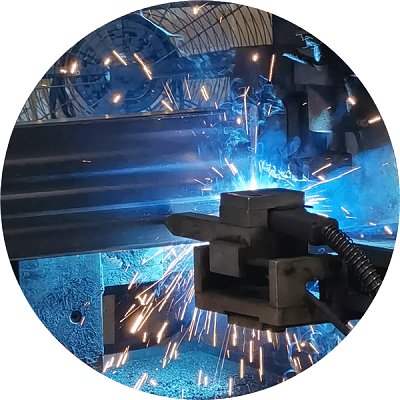

Drive in Pallet Racking Production Process

Leave a Message

Related Pallet Racking Systems

Selective Pallet RackingSelective Pallet Racking is the most economical pallet racking solution, 100% selective

Selective Pallet RackingSelective Pallet Racking is the most economical pallet racking solution, 100% selective Narrow Aisle Pallet RackingNarrow Aisle Pallet Racking-high density solution, the aisle is just need 1.6m-1.8m

Narrow Aisle Pallet RackingNarrow Aisle Pallet Racking-high density solution, the aisle is just need 1.6m-1.8m Double Deep Pallet RackingDouble Deep Pallet Racking-four bays together, high density, need the special double deep forklift

Double Deep Pallet RackingDouble Deep Pallet Racking-four bays together, high density, need the special double deep forklift