Company

Quality Control

"Quality First, Safety Loading the most important", as a professional racking supplier, we always emphasize this term in our company, pay attention to the quality in the whole production process. We also have a thorough quality control system.

01

Raw Material Selection

· We select the steel supplier carefully, there are some factors, only when the suppliers fix our requirements, then, their name can be showed in our company qualified supplier form, we can choose the ones to purchase the materials only in the form list.

· When the materials arrived in our factory, before unload to our warehouse, IQC must confirm the quality firstly: check specification certificate is ok, visual inspection the incoming materials, check the surface appearance, measure the size, thickness, must conform to the National Standard, sometimes, our company standard even is stricter than the national standard. The inspected, qualified materials can be loaded in warehouse, if not qualified will be return back.

Before bulk order being processed, we must confirm the first piece is no problem, that's very important step, the first sample will be showed in site, for the next process to confirm the quality.

02

First Piece Inspection

03

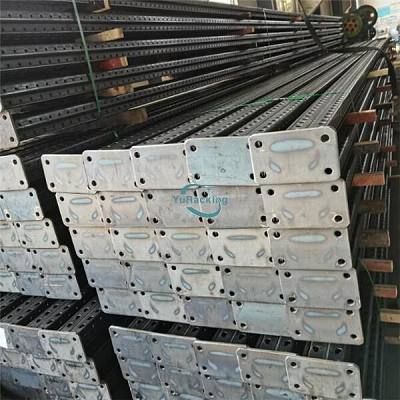

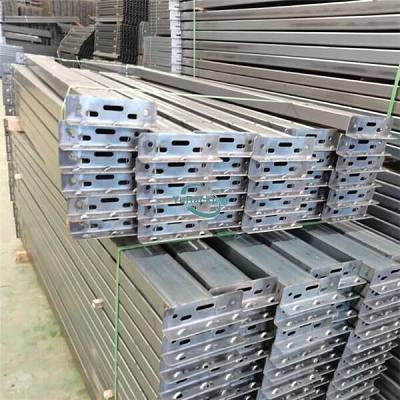

Process Control

The IPQC, control the whole production process, their ordinary job duties: keep the qualified products on the line, unqualified, can't accept. From stamping, rolling, bending, welding, powder coating, step to step, select the defective products, keep the qualified ones go to next step.

Post hole Punching to Rolling to bending to welding to powder coating to the final sample checking

Confirm the color, powder coating thickness, surface appearance, confirm all the painting details same as the sample required.

Packing must be suitable for oversea shipping:

· The wood needs to be: plywood or natural wood with Inspection Certificate of Fumigation.

· All the forklift contact parts need to be protected, avoiding damage when loading and unloading;

· The outside parts need be covered with plastic film;

· Use steel band fix the whole pallets tightly, if products are long, for example some post is over 6m, some beam are over 3m, need to fix much better.

04

Final Finished Products Control (Powder Coating and Packing)

05

Container Loading

Confirm the pallets are in the container properly, if there is empty space between the pallets, filled with bubble pack, make sure they are not hit each other in the container when happens shaking in the shipping process.

If there are some items may fall down, will fix them with steel/plastic band, or wire net, avoiding any accident happened when open the container door.