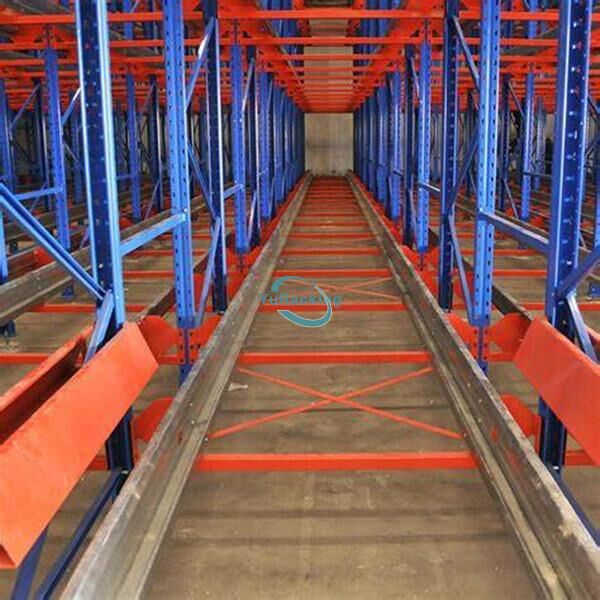

Shuttle Pallet Racking is a semi-automatic high-density solution, forklift no need go into the racking areas, the shuttle car load/unload the pallets in and out of the channel along the rail automatically, controlled by a wireless remote control. The pallet shuttle racking system is space saving, labor saving at the same time, really a high cost-effective solution.

Pallet Shuttle Racking, usually, we always compare it with the drive-in racking system, which need the forklift operator goes into the racking area to load/unload the pallets, the pallet shuttle warehouse automation system, on the contrary, just need the forklift operator send the pallets to the shuttle car, then, the shuttle car will load the pallets into the deep lane one by one automatically, the laser on the shuttle car can find the exact location to put the pallets by itself. The Radio/Video Shuttle Racking system, not just save space (the depth of the rail can be 20m-50m, that is around 50 pallets position in the depth lane), and with no aisle between the channels, greatly improved the productivity and efficiency, the shuttle car can run 60m/min without loading, 42-48m/min with loading. As the good structure design, no need many extra maintain to the whole system, damage to the system also decreased greatly. Lots of the advantages of the shuttle racking system make it a good choice for you.

The Features of Shuttle Pallet Racking

FILO or FIFO mode, both are available;

High space use, no need aisle for the rows;

Fewest aisle, the whole racking area in rows one next to the other;

Semi-automatic, most work can be finished by the shuttle car automatically;

Easy to handle, easy to learn the operation of the shuttle car;

Space saving, labor saving, warehouse flow speed greatly improved;

Minimizes damage to the rack because no need the forklift go into the racking area.

The Specification of Shuttle Pallet Racking

Shuttle Racking Upright Frame Load Capacity

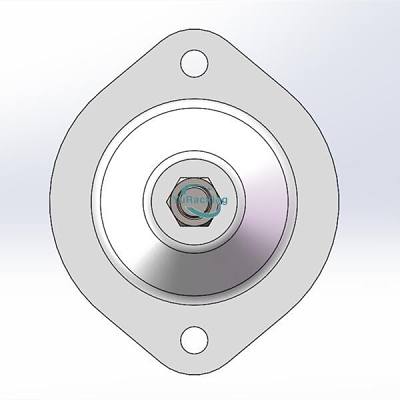

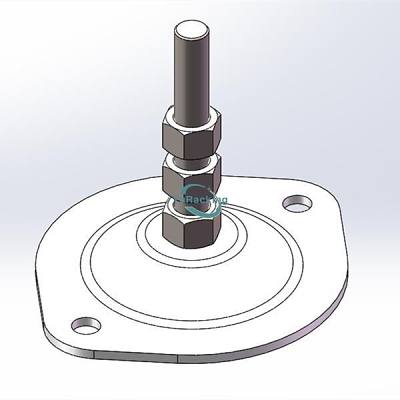

Shuttle Racking Parts & Accessories

Shuttle Racking Production Process

Leave a Message

Related Pallet Racking Systems

Selective Pallet RackingSelective Pallet Racking is the most economical pallet racking solution, 100% selective

Selective Pallet RackingSelective Pallet Racking is the most economical pallet racking solution, 100% selective Narrow Aisle Pallet RackingNarrow Aisle Pallet Racking-high density solution, the aisle is just need 1.6m-1.8m

Narrow Aisle Pallet RackingNarrow Aisle Pallet Racking-high density solution, the aisle is just need 1.6m-1.8m Double Deep Pallet RackingDouble Deep Pallet Racking-four bays together, high density, need the special double deep forklift

Double Deep Pallet RackingDouble Deep Pallet Racking-four bays together, high density, need the special double deep forklift