Pallet Racking System

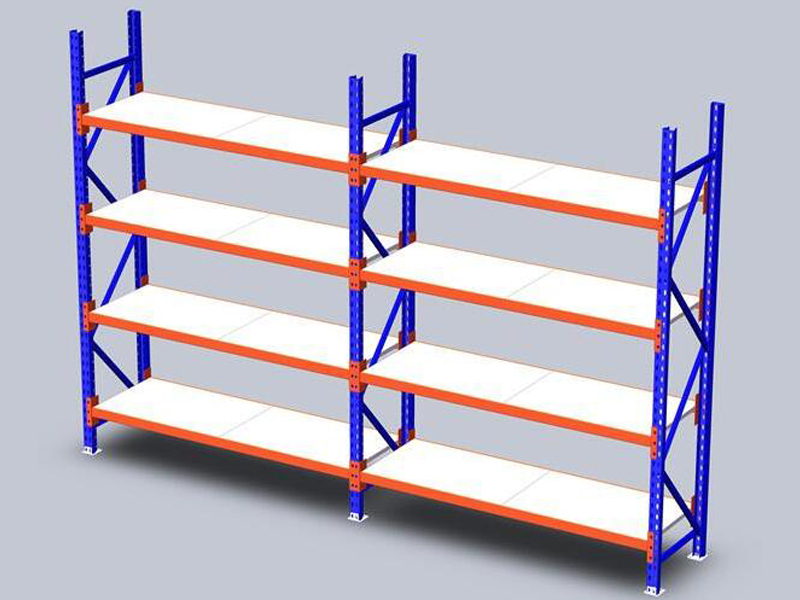

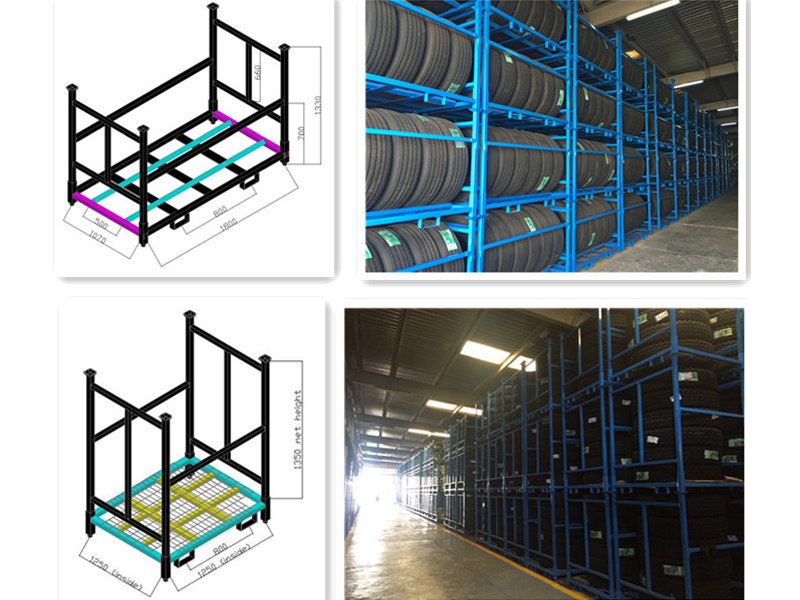

Warehouse pallet racking system is a universal system for forklift loading of pallets cargos. The main parts of pallet rack shelving include upright (frame), beam, and other accessories. When using this kind of warehouse pallet racks, the goods need to be placed on the pallet first, then stored in the corresponding position of the shelf by forklifts. The biggest advantage of this pallet storage racks lies in its relatively strong stability and load capacity. Therefore, this pallet storage system is more suitable for storing a variety of small-batch items or a large volume of items in different kinds. Pallet rack shelvings have high utilization rate, and it is flexible and convenient for operators to access goods. If the warehouse pallet racks are supplemented with a computer management or control system, a modern logistics systems of warehouse pallet racking is formed. Pallet racking is widely used in warehouse, cold room, big chain stores, such as Sam's club, Home Depot...from drink/food, furniture, tire, fodder industries to electronic industry.

Load capacity: 1000-4000kg/level. The main parts of pallet storage solutions include upright (frame), beam, and other accessories.

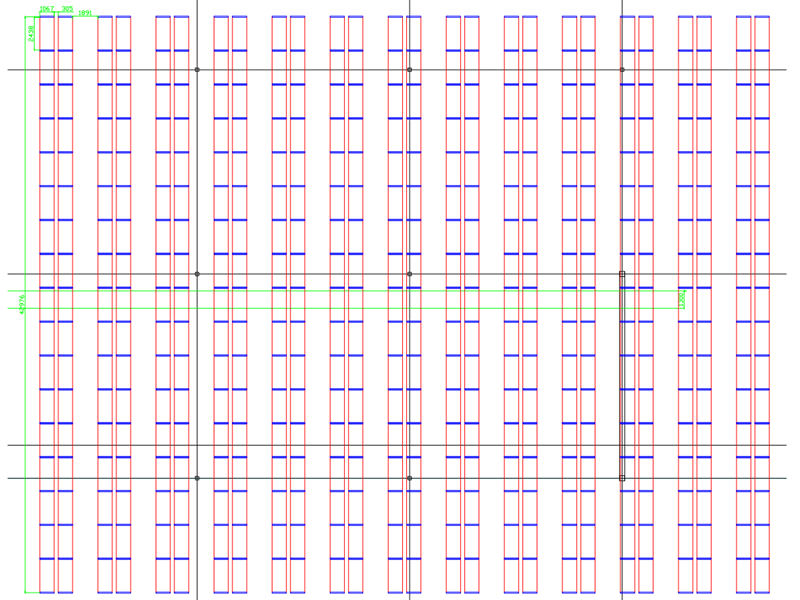

Focusing on pallet rack warehouse & supply for many years, YuRacking, a reliable pallet racking manufacturer, also a professional pallet racking supplier, has different types of pallet racking for sale. All with affordable pallet racking prices, and can be chosen according to your warehouse situation, estimated storage cost, and cargos to keep. We are one-stop shop racking & shelving provider, from pre-consulting, layout design/CAD drawing, installation... not only supply racking itself, the main strengths is our series service, pre-sales service and after sales service. We will provide the most suitable racking system and materials handling equipment for your warehouse. Any need, email us: info@yuracking.com or call us: 86-18120162582, the professional engineers and experienced installation team will be here for your warehouse.

Different Types of Warehouse Pallet Racking for Sale

Selective Pallet RackingSelective Pallet Racking is the most economical pallet racking solution, 100% selective

Selective Pallet RackingSelective Pallet Racking is the most economical pallet racking solution, 100% selective Narrow Aisle Pallet RackingNarrow Aisle Pallet Racking-high density solution, the aisle is just need 1.6m-1.8m

Narrow Aisle Pallet RackingNarrow Aisle Pallet Racking-high density solution, the aisle is just need 1.6m-1.8m Double Deep Pallet RackingDouble Deep Pallet Racking-four bays together, high density, need the special double deep forklift

Double Deep Pallet RackingDouble Deep Pallet Racking-four bays together, high density, need the special double deep forklift Drive in Pallet RackingDrive in Pallet Racking-no aisle in a certain area, one bay next to one bay, space saving

Drive in Pallet RackingDrive in Pallet Racking-no aisle in a certain area, one bay next to one bay, space saving Shuttle RackingShuttle Racking-shuttle car load/unload pallets into the bay automatically, save space, save labor…

Shuttle RackingShuttle Racking-shuttle car load/unload pallets into the bay automatically, save space, save labor… Teardrop Pallet RackingTear Drop Pallet Racking-upright surface shape is like a teardrop, wildly used in America market

Teardrop Pallet RackingTear Drop Pallet Racking-upright surface shape is like a teardrop, wildly used in America market Pallet Racking Wire DeckingPallet Racking Wire Decking-wire decking on the rack, store products or pallets on them directly

Pallet Racking Wire DeckingPallet Racking Wire Decking-wire decking on the rack, store products or pallets on them directly Push Back Pallet RackingPush Back Pallet Racking- push pallet into the depth direction one by one

Push Back Pallet RackingPush Back Pallet Racking- push pallet into the depth direction one by one Pallet Flow RackingPallet Flow Racking-pallets flows into the depth by gravity design

Pallet Flow RackingPallet Flow Racking-pallets flows into the depth by gravity design

Benefits of Pallet Racking for Your Warehouse & Logistic & Product Display System

-

The load capacity of our warehouse pallet racking is ususally 1000-4000kg/level, also can customized as your special demands;

-

Different types and sizes of pallets can be desighed and fixed on our pallet rack storage system, pallet rack material including steel/wood/plastic pallets;

-

Well organized pallet racking and shelving can improve your warehouse loading efficiency and keep your warehouse in good order;

-

Effective pallet storage solutions can help you improve the efficiency of your storage and save labour costs;

-

Warehouse pallet racking system are widely used in almost all industries, retail and general warehousing; Palletized design make your storage much more easier;

-

A wide range of design/distribution /layout solutions for pallet storage warehouse can be chosen;

-

Widely used in almost all industries, retail and general warehousing;

-

We have technical engineer team, can design the pallet racking layout according to your warehouse situation and your loading requirement, making the most suitable solution for your warehouse. We not just sell pallet racking and warehouse shelving, but offer pallet racking solutions, arrange delivery/oversea shipping, installation, after sales service.

What is Pallet Racking Storage System and How Does Pallet Racking Work?

The pallet rack shelving is used widely in almost all warehouses. Main parts of Pallet Racking include upright frame and beam. Different types of holes are punched on the upright, and through the rolling machine, these upright are made into different types of upright frames. The beam is also shaped by a rolling machine. And there are different sizes of sections made: 80*50; 100*50; 110*50; 120*50;130*50;140*50;160*50...

Pallet storage system is divided into many kinds: selective pallet racking, double deep pallet racking, VNA pallet racking, drive in pallet racking, shuttle pallet racking... suitable to different working environments, and can be used to store almost all cargos. The forklift can get the cargos/pallets from two sides of pallet storage shelves very easily. Usually, people distribute single lines aside from the wall, and the middle parts are often back-to-back. The aisle between pallet racking and shelving is usually 3.3-3.5m.

Pallet Racking Weight Capacity

We have different materials with different section size, thickness from 1.0mm-4.0mm, choose the suitable materials as the loading requirement.

How to calculate pallet rack load capacity?

It depends on the weight of the goods/cargos, usually, we calculate the weight of the pallet with goods on it, for example, the weight of the pallet goods is 1000kg, we design two pallets/level, then, the load demand is 2000kg/level, then, we can choose the materials satisfy 2000kg according to the beam length. And for the upright frame, need to calculate all the level loading, for example, 2000kg/level, totally 5levels, then, the frame loading is 2000*5=10000kg/frame.

How to determine pallet rack capacity or how much weight can a pallet rack hold?

That's a result by test, after calculate the theory of the materials' loading, will make the actual test, to confirm the load capacity of the beam and the frame. And there is a pallet racking weight limits, load deflection: L/250 or L/300.

There is detailed pallet rack load capacity chart in the details page of pallet racking

How to Choose Pallet Racks and What will Influence the Pallet Racking Prices

The factors need to consider when choosing the types of pallet rack you need: warehouse size (floor space, height, useful space), kinds of inventory(size/weight), storage density, rate of stock turnover, forklift type, project budget... all these factors will influence which racking system to choose.

What will Influence the Pallet Racking Prices

The factors that determine the price of pallet racking mainly include the following aspects, which you can consider when purchasing a racking system.

1. The types of pallet racking, different storage demand with different type of pallet racking, will make a big difference on the price;

2. The quality of the steel type, different materials, surface powder coating quality, in a different price;

3. Installation is a paid service;

We know pallet racking price is also an import factor to decide buy or not, with our professional technical engineer team, can provide the most reasonable racking solution for your warehouse, make it a high performance project, keep your inventory demands also save your budget. Welcome inquiry now!

FAQS of Warehouse Pallet Racking Wholesale

Does pallet racking need to be certified?

Yes, certified, with CE certification, pallet racking can be widely sold all over the world. Yuracking provide: FOB, CIF, Door to Door delivery service for our bulk sale pallet rackings.

What's pallet rack material do you use?

As one of the professional warehouse racking suppliers, Yuraking uses steel Q235, which is a carbon structural steel, due to the moderate carbon content, the comprehensive performance is better, good plasticity, toughness and cold deformation performance, these advantages make it widely used in pallet racking industry.

How to install pallet racking and storage shelves?

As a professional pallet racking company, we always provide pallet rack installation instruction to our customers, you can see detailed pallet racking intallation guide here. Your workers can finish pallet racking installation by themselves with our engineer's installation guide drawing and video.

Also, we offer specialized warehouse racking installation services, our installation team can help you finish the whole project, or we send an engineer to guide your workers to finish some sample bays, and teach your workers till they can finish by themselves.

how much space do you need between pallet racks/pallet racking spacing for forklift?

The standard pallet rack spacing depends on the different types of pallet racking systems:

1) The commonly seen wide span pallet racking, also called selective pallet racking, its spacing is usually 3m-3.5m;

2) The very narrow aisle pallet racking, also called VNA pallet racking/ Narrow Aisle Racking, its space is usually 1.6-1.8m;

3) The double deep pallet racking, four bays (two back-to-back racks) together, the space is usually 3m-3.3m;

4) The drive-in racking, in a whole racking area, there is no space between the bays, just need a main aisle in the middle parts for the forklift, so, we can say there is no space between the drive-in pallet racking. While, in some warehouses, also can be designed to Drive Though Racking.

5) The pallet shuttle racking, same as drive in racking system, one bay next to another bay, no space need in the racking area;

6) The pallet rack distance from the wall, usually, around 200mm-300mm, if the racking is very high above 6, will use wall connector to connect the pallet racking to the wall, increasing the stability of the racking system.

Both the drive-in racking system and the pallet shuttle racking system are very high-density racking system, and they can save space greatly, can be FIFO (first in first out).

How to secure pallet racking, espacially for heavy duty pallet racks?

As we always emphasize, the quality and safety loading are the most important thing when using pallet rack shelving. We need to secure the pallet racking in our daily usage process, fix some essential protector parts for the pallet racking system. That's a basic concept needed to be deeply rooted into the minds of all warehouse stuff, especially the warehouse front line workers, such as the forklift operators…

Pallet racking Inspection is very important too. You should choose the professional engineer in charge of the inspection work, inspect the warehouse racking system time to time, make sure all the racking systems work in a good condition, find and replace the defection ones timely.

What size of pallet racks should I choose?

It demands on the pallet size you use, the pallet length, depth, height (pallet height + goods height), warehouse size, especially the height of your warehouse. You can call YuRacking to have a more professional suggestion (86-18120162582) or email: info@yuracking.com. Our technical team and sales team, not only can tell you the size of pallet racks you need, but also will cooperate with you to find the most suitable racking solution for your warehouse.

What's the standard size of pallet rack?

There is three different common size: L2700*W1000*H5600/7500/8500, used in Asia market mostly; 2) L2700*W1000, or L2300*W1000, used in Europe market more; 3) L96"*D42"*H18' or L44"*D46"*H28', used in North America market more; Actually, the racking size depends on your own cargos storage requirement more, that means we can choose the suitable size as your warehouse need, you can choose the one you like. No need to consider the standard size too much.

Can I purchase pallet rack in non-standard sizes?

Of course, we not just can provide non-standard sizes of pallet racking, also can customize some special type as your special inventory loading requirement. Our professional engineer team can customize/design as your demands.

Do I have to anchor my pallet rack system to the floor?

Yes, the heavy-duty pallet racking must use anchor fixed to floor tightly, there is two hole in the pallet racking footplate, which is used for the anchor into the floor, in this way, avoid falling down of the frame, can keep the stable of the post/upright, and keep the stability of the whole racking.

Expert Advice on Racking and Shelving Solutions